That's New Year soon! Christmas tree decorations appear on store shelves next to tangerines, sweets and champagne: colorful balls, tinsel, all kinds of flags, beads and, of course, electric garlands.

Perhaps you can’t buy an ordinary garland of multi-colored light bulbs. But various flashing lights, mostly made in China, simply cannot be counted. Microscopic light bulbs can be placed on a piece of cardboard or woven into a carpet of wires that can decorate an entire window at once.

Christmas tree garlands are also very diverse, especially external design, design. The cost of such garlands is low, as, in fact, the power of light bulbs.

Most string lights come in a small plastic box with a single button, a cord with a mains plug, and wires that go to a string of colored lights. The design of the garland can be very diverse.

The simplest and cheap option consists of microscopic light bulbs inserted. On the back of the packaging box, instructions for changing bulbs and safety instructions are written, although spare bulbs are not included. It is these garlands that are sold in the Vse po 38 chain of stores, however, recently for forty rubles.

Figure 1. Garland for forty rubles

Garlands of a different style have small plastic shades on the bulbs, for example, in the form of transparent flowers with petals. But the box with the button remains the same, although the price of the garland reaches two hundred rubles. Let's try to open the box and see what's inside.

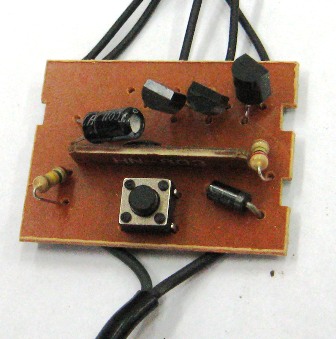

Figure 2. Appearance string controller with three thyristors

At the bottom of the figure, two wires are shown, this is just connecting the device to the network. There is also a button with which the operating modes are switched. In the upper part you can see three thyristors and wires leading to the garlands.

In the middle of the board is , - such a black drop mounted on a small printed circuit board. The board has contact pads, with the help of which the controller is soldered into the main board.

How many thyristors on the board

The control electrodes of thyristors are connected to the outputs of the microcontroller, which turn on the garlands of light bulbs. The microcontroller has four outputs, but often, instead of four thyristors, only three are installed on the board, and in some cases only two.

Necessary visual effect is achieved by connecting garlands and the arrangement of light bulbs: bulbs of two or even three colors are soldered in one garland. Just such a board is shown in Figure 2.

If you look at this board from the PCB side, you can see that three thyristors are soldered, and under the fourth there are holes with tinned pads, as shown in Figure 3. In some cases, the holes are not even drilled, they say, whoever pleases, will drill himself .

Figure 3. Fairy controller board. Free place for thyristor

The following feature should be noted here: if the controller output is not connected anywhere, this does not mean at all that it is not working. The program in all controllers is flashed, apparently the same, all controller outputs are involved.

This is easy to verify with the arrow tester. If you measure the constant tension on the free leg, then the arrow will jump, twitch and deviate along with the flashing of other garlands. It is enough just to solder the missing thyristor into the board, and, please, we get a full-fledged four-channel garland.

The thyristor can be taken from an old faulty board (it happens that the controller becomes unusable) or you can buy an additional garland for forty rubles and remove the thyristor from there. For a good cause, the costs are extremely small!

Schematic diagram of a garland

It is easy to compose on a printed circuit board circuit diagram. There are two types of schemes, slightly different from each other. The first, most advanced option is shown in Figure 4.

Figure 4 Controller chinese garland. Option 1

The entire circuit is powered through VD1 ... VD4. The garlands are powered by pulsating voltage and are switched on by the controller through thyristors VS1…VS4. Resistor R1 and microcontroller DD1 form a voltage divider, the output of which is a voltage of 12V.

Capacitor C1 smooths out the ripple of the rectified voltage. Through the resistor R7, the mains voltage is applied to the input of the controller 1 to synchronize the circuit with a network frequency of 220V, which allows phase control of the thyristors. This synchronization allows for smooth ignition and extinction of garlands. It is these boards that can be found in expensive garlands.

The board shown in Figure 3 is assembled according to a somewhat simplified scheme, which is shown in Figure 5.

Figure 5. Chinese garland controller. Option 2

It immediately catches the eye that there are only three thyristors, and only one diode remains from the rectifier bridge. The resistors from the control electrodes of the thyristors also disappeared. But, in general, consumer properties remained the same as in the previous circuit, despite the fact that the bulbs are lit only when there is a positive half-cycle of mains voltage on the upper wire of the circuit. Without a rectifier bridge, half-wave rectification is obtained.

This version of the circuit solution is inherent in those garlands that are "all forty". That, in fact, is all that can be said about the circuitry of Chinese Christmas tree garlands.

How to connect powerful lamps

The power of the garlands is small, the bulbs are simply microscopic, except for a homemade Christmas tree, they are unlikely to fit anywhere else. But sometimes it is required to connect a garland with powerful incandescent lamps, for example, for decorative illumination of building facades. Such a refinement has already been given in the article. The scheme of the modified garland is shown in Figure 8 in the mentioned article.

If you don't want to redo the board

Much easier to do without reworking the controller board. All you have to do is to make four powerful output switches with optocouplers and connect them instead of low-power garlands. The power switch circuit is shown in Figure 6.

Figure 6. Powerful power switch with optocoupler isolation

Actually, the scheme is typical, it works flawlessly, it does not contain any pitfalls. As soon as the LED of the MOC3021 optocoupler lights up, a low-power optocoupler thyristor opens and the control electrode and anode of the BTA16-600 triac are connected through pins 4, 6 and resistor R1. The triac opens and turns on the load, in this case a garland.

The optocoupler should be used without the built-in CrossZero circuit (mains voltage zero crossing detector), for example, MOC3020, MOC3021, MOC3022, MOC3023. If the optocoupler has a CrossZero node, then the circuit WILL NOT WORK! This should not be forgotten.

Triac BTA16-600 has the following parameters: forward current 16A, reverse voltage 600V. At a current of 5A and a voltage of 220V, the load power is already a whole kilowatt. True, you will need to install a triac on the radiator.

The metal substrate is isolated from the crystal, as indicated by the letter A in the triac marking. This makes it possible to install triacs on a radiator without mica gaskets and screw insulators. By the way, it is these triacs that are in the power regulators of household vacuum cleaners, while the radiator is blown by the air flow at the outlet of the vacuum cleaner.

If the load power is not more than 400W, then you can do without a radiator. The pinout of the triac is shown in Figure 7.

Figure 7. Triac pinout BTA16-600

This drawing will not be superfluous at all when assembling the power switch circuit. All four power switches are best assembled on a common printed circuit board. Resistor R is best assembled from two 2W resistors, which will avoid excessive heating. The maximum current of the input LED of the optocoupler is 50mA, so a current of 20 ... 30mA will ensure its long-term trouble-free operation.

Figure 8. Connecting power switches to the controller board

In general, everything is clear and simple. The garlands are soldered from the controller, and instead of them, the input circuits of the power switches are soldered. This does not require any intervention in the printed wiring of the controller. The only exception is the soldering of an additional thyristor, provided that it can be found. You will also have to somewhat strengthen the power cord with a plug, since the original one has a very small cross section.

With proper installation and serviceable parts, the circuit does not need to be configured. The design of the device is arbitrary, best of all in a metal case of suitable dimensions, which will act as a radiator for triacs.

In order to ensure electrical safety, the device should be turned on through a circuit breaker, or at least a fuse.

How to fix a Chinese garland: a diagram. Chinese garland scheme

Dangerous Chinese Garlands

Hello friends! Fairy times are coming: children and adults have holidays, a Christmas tree on the balcony, vodka and sausage in the refrigerator. Have you already brought the Christmas tree? Are you dressing up? It's clear. And they probably saved on garlands, Schaub was enough for sausage. Then take your time. Conduct an audit of the products of the Chinese brothers before winding them on a festive tree. Chinese garlands are good at a low price. This is where the charms end, and the troubles begin: from fading in the midst of fun to electric fireworks with a fire.Option one, classic

Photos of my fellow countryman Pavel Shepelev. A garland of colored incandescent bulbs, a control unit in a green box. with fire and stench, as much plastic flowed. The control unit burned out completely, the reasons are not guessed. Treatment: the green box is fucked up, the garlands are in parallel. The garlands shine, though they do not blink.Option two, fashionable

Multi-channel multi-mode garland on LEDs (light-emitting diode). Good for everyone: bright and colorful and not afraid of concussions, BUT! The Chinese again even wised up for economic reasons. In series with each branch of lights there is a 3 kOhm resistor and some kind of inhumanly low power, I believe - less than 0.125W! There are 10 such resistors in total. and they all heat up fiercely. And the meanness is that it is not noticeable. You won’t even guess about the existence of these resistors until they start to burn - they are so cunningly mounted. This garland worked for 1 NG. That's what was found during the inspection today. Low-power resistors overheated, burned, even soldered from the LEDs and wires. Only the outer plastic clip kept them in place. When disconnected, the solder cooled down and everything could be started from the beginning. The malfunction did not appear! The plastic clip was cut with a clerical knife, the resistor was replaced. The procedure was done for all detected resistors. 2 hours - normal flight!Dear fellow citizens, I urge you to take seriously such a not serious, fun thing as a New Year's garland! Look, measure, feel. It raises doubts - take away from sin. All happiness and kindness in the hut in the New 2013!

Igor Kotov (Datagor)

Russia, Siberia, Novokuznetsk

Founder, owner and chief editor of the Journal of Practical Electronics datagor.ru.Founder, owner and chief editor of datagor.ru.

datagor.ru

Almost every family has a broken Chinese New Year garland in need of repair. December always comes and takes families by surprise, who, just the day before, decide to put up a New Year tree and decorate it with beautiful garlands.

As a rule, we find out that a Chinese garland needs repair at an inopportune moment. It’s not at all a hunt to spend money on a new thing, and not everyone can manage to repair the New Year’s Chinese miracle on their own.

Now we will look at how a simple Chinese garland with adjustable luminescence frequency works, common malfunctions, troubleshooting methods and how to fix them. Everything will be described in detail in the article, clearly shown in the photographs. Everything will be convenient for restoring its performance on its own. To cope with such a repair, it will be possible for almost every person.

Schemes of New Year's garlands

Serial connection of paws

To begin with, consider the simplest scheme of the New Year's garland. This serial connection of incandescent bulbs, in the Soviet years, was the most common scheme. Every house had a similar garland.

In a serial connection, all the bulbs are connected in a chain, in a wire break and connected to a power source, generator, home wiring, battery. In this case, the same current flows throughout the garland.

There was no smell of LEDs, of course. She was forced to blink by starters taken from fluorescent lamps at school. Starters were simply included in the circuit, like light bulbs, in series.

A few words about starters and their meaning. It's simple discharge lamp, placed in an aluminum, paper or plastic case. For convenience, a viewing hole is made in the case.

It consists of two bimetallic electrodes, which, bending from the passing current, close and open the electrical circuit. After that, the Christmas tree garland began to blink rather quickly.

This scheme is very simple and convenient, but has a significant disadvantage. When one bulb burns out, the electrical circuit breaks and the entire garland goes out.

Parallel connection

Modern Christmas Chinese garlands are included in a parallel electrical circuit. Thus, they prolong the life of the garland, and delay repairs for a long time.

The whole thing is that with a parallel connection of light bulbs in a Christmas tree garland, the voltage remains the same on each element of the circuit. What gives a lot of advantages, the main thing is that when any bulb in the circuit burns out, it does not break and the garland continues to work. As for the current strength, it is different for each element of the circuit.

This scheme is most common in home wiring, due to its reliability, convenience and simplicity.

The main malfunctions of New Year's garlands

We simulate the situation, you take out your Christmas decorations and New Year's garlands from the closet, start decorating the Christmas tree, plug it into the power supply, and nothing happens. Disappointment and despair on the faces of your children, faith in New Year's magic disappears, the holiday failed.

It is still possible to fix everything, even if there is fifteen minutes of backwardness before the chiming clock, with the help of one’s own strength and an uncomplicated tool.

The garland shows no signs of activity at all. We look at the electrical plug, nicknamed its integrity as a device. To do this, we disassemble the control unit of the Chinese garland, and look at the contacts that come from the electrical plug.

We put the switch in the measurement of diodes, press one probe to any contact of the plug, and apply the second to the wire contact on the control unit board. If it emits a squeak, then the wire is working, if not, then it is broken. With the second contact, we do exactly the same. Both turned out to be intact, we look for a malfunction further, if one is open, we change this part of the wire along with the plug, and turn it on again. It burns normally, we rejoice, no, we search further.

A small addition, a Chinese garland blink cycle control unit, is located on the wire, immediately after the plug. This is that green box with a button, by clicking on which you change the blinking frequency of the New Year's.

How to test a light bulb from a garland

If the garland is made with a series connection of bulbs, then most likely one of the bulbs has burned out. Electrical circuit open, and current can only flow through a closed circuit.

To restore the performance of the Chinese New Year's toy, you just need to replace the damaged element. But, first you need to check the light bulb, which is under suspicion.

It can be checked by external inspection, the easiest way, in a glass vacuum bottle, is an incandescent spiral. When passing through a current spiral, it begins to glow, in the spectrum visible to our eyes. If it burned out, it will be visible to the naked eye.

You can check it with a tester, for this we put the switch in the resistance measurement mode. We connect the probes to the electrodes of the incandescent lamp, and look at the display of the digital tester. A working light bulb from a garland should have resistance, and quite large, if it is absent, then we change it.

You can check the light bulb from the garland, using an adjustable power supply, who has it, of course. We connect the bulbs to the terminals, set the voltage to 1.5 volts, the spiral should glow a little. You can add a little voltage, although one and a half volts is enough.

If all the bulbs and the power cord with an electric plug rang, everything is fine, but for some reason the garland does not work? We are looking for a wire break in the garland itself.

It’s a little easier here, we set the tester to the diode test mode, put one probe at the beginning of the wire on the board itself, push the second to the wire inside the cartridge, where the light bulb was. We heard a squeak, so the wire is whole, we put the probe on the next wire in the base, and continue the procedure until the end of the New Year's garland.

Garland control unit repair

It happens that the control unit for flashing garlands is to blame, possible malfunction, simple separation of the wire from the board, as a result of a strong jerk or cold, poor-quality soldering, other problems.

To fix the problem, you need to disassemble the plastic box with the control unit itself. On the reverse side there are two screws for a “plus” screwdriver, curly, unscrew them and carefully remove the board.

On the board we see a circuit consisting of elements, an electrolytic capacitor, two transistors, four diodes, one miniature button. The board contains a frameless microcircuit, which looks like a black drop, and a pair of resistors.

The capacitor in the control unit of the Chinese garland, an electrolyte is installed, which means it has polarity and must be observed. On the board that I have, it has a rating of 10 microfarads, at 25 volts. Transistors PCR 406, if suddenly during the operation of the New Year's garland, one of the transistors exploded, most likely, the second one will be completely identical. Diodes, all four are marked, IN 4007, a very common diode, there will be no problems with replacing.

As for the frameless microcircuit, its denomination is written on the reverse side, B - 803, although in most cases, it is known only to the manufacturer.

Troubleshooting Christmas Garland

We are starting to repair the control unit, the Chinese New Year's garland. We solder all the contact points on the board, it happens that cold soldering is not noticeable to the eye, so we perform normal soldering, everywhere.

The next step is to check the semiconductors, these are diodes and transistors. Their check is carried out by a tester, the diodes must be checked in one direction, and practically do not pass the signal in the opposite direction.

Transistors need to be soldered, for a more accurate check, we check with a tester. We replace damaged parts with new ones or with known good ones suitable for repair.

Capacitor, resistors and mini button, just check for integrity. When checked, they must not show a short circuit and complete absence resistance.

If you followed all the recommendations for repairing an electric garland, and it did not work. You can exclude this block from the circuit, and connect the wires in a straight line. You can also completely change all the wires. Of course, this is long and laborious, but for beginner radio amateurs, it will be an excellent practice.

energytik.net

How New Year's garlands are arranged - Energy Articles

Christmas garlands for decorating Christmas trees began to be used at the end of the 19th century. They replaced the unsafe New Year's candles with which New Year's trees were decorated. Then it was the simplest garlands of multi-colored light bulbs. Now the variety of New Year's garlands provides a wide choice to buyers. In the article, we will consider the device of various New Year's garlands, starting with the old simplest circuits and ending with modern garlands with microprocessor control.The simplest version of a New Year's garland can be several light bulbs connected in series. If you give the bulbs a multi-colored color and give some kind of lighting effect, then such a New Year's garland will attract much more attention and create a festive mood. Various control schemes for New Year's garlands were published in radio magazines in the New Year's Eve.

The scheme of the New Year's garland with alternately smooth ignition and extinguishing of the LEDs is shown in Figure 1 (author A. Chumakov). Distinctive feature scheme is that the adjustment of the rate of extinguishing and ignition is carried out by a separate control unit.

Picture 1

With the introduction of microprocessors in amateur radio circuits, more and more often, the management of New Year's garlands was shifted to them. A. Pakhomov proposed a scheme for controlling a garland from a cell phone (Figure 2) in the Radio magazine No. 11, 2012. The scheme is based on a control board from a Chinese garland with a replaced AT89C51 controller. The cell phone, on the other hand, serves as a control panel for the circuit.

Figure 2

Enough a simple circuit LED New Year's garland was proposed by I. Nechaev (Radio magazine No. 11, 2012, Figure 3). Three-color RGB-LED lamps are used as LEDs, each channel of which operates independently and is controlled by its own DB-3 symmetrical dinistor.

Figure 3

However, homemade New Year's garlands are already quite hard to find anywhere. Christmas decorations from China have practically filled the store shelves. The cost of such garlands is minimal, and the time and money spent on making a New Year's garland on your own is much more serious. The control schemes for Chinese New Year garlands are very fast (Figure 4). A microcontroller (a drop of black compound), a control button, a capacitor, a diode and three output thyristors are hidden in a small plastic box. The control scheme of the Chinese New Year garlands has been slightly changed. Initially, the circuit (Figure 5) provided for the installation of four thyristors, however, Chinese craftsmen save a little on the element base and even install two thyristors in some circuits. A single diode serves as a rectifier. It is worth noting that manufacturers from China often save on current-limiting resistors for LEDs.

Figure 4

Figure 5

It is worth noting one feature of the above scheme. Resistor R7 connected to the microcontroller (pin 1) is used to synchronize with the network. This allows for phase power control with smooth turning on and off of the LEDs. To switch between control programs (light effects), a button is used, which is also connected to the microcontroller input.

The control circuit of a New Year's garland with a power of several hundred watts is shown in Figure 6. It is almost similar to the previously considered circuit, except that the microcontroller is powered by a separate power supply with galvanic isolation with a network.

Figure 6

ukrelektrik.com

CHRISTMAS GARLAND SCHEME

How to make a Christmas tree garland yourself using inexpensive affordable components. I assembled this simple scheme on New Year's Eve d-tsat years ago, and so far it honestly works on every New Year's holiday. A garland according to the scheme below allows you to create an interesting lighting effect that is not found in purchased controllers. Chinese devices management.

Schematic diagram of a Christmas tree garland on microcircuits

The microcircuits are powered by a parametric stabilizer on the D814D. The master oscillator is assembled on K176IE12 with a quartz resonator with a period of 1 second. The signal from it goes to the K561IE8 decoder. Positive pulses through the diodes are fed to the control transistor KT315, resulting in the opening of the thyristor.

There are enough LED garlands on sale, but for a softer and more festive cozy glow, it is better to use ordinary light bulbs. The lamps of the garland are connected by both branches to a bridge rectifier and burn at full heat. At the moment the thyristor opens, some of the lamps are shunted and the rest begin to glow at full incandescence - this must be taken into account. The transformer is taken from a suitable home appliance.

Unlike most garlands from the store, mains voltage decoupling is implemented here, that is, if children accidentally touch the lamp power wires, nothing bad will happen, since they have safe voltage. With respect, Nicholai.

elwo.ru

The month of December has come, and it's time to decorate the apartment with all kinds of New Year's decorations, including garlands. Here it begins to be remembered that last year someone tangled through a Chinese LED garland and cut off the board with torn wires so that it only remained to throw it away.

There are similar situations great amount, but the result is the same for most: the board with the programs burns out, and the groups of light bulbs or LEDs remain intact. It is a pity to throw them away, but few people know how to apply them. In this state, the garland can lie for more than one year without repair. In this article I will tell you how a similar problem was solved by me. The test subject was a 100 LED Chinese LED garland, with four groups of 25 LEDs, respectively.

I did not set the task of super smart programmed blinking of the garland. I wanted the LEDs of the garland to not just tediously burn without any signs of “life”, but wink briskly, setting a festive mood. Then I remembered the old simple proven Soviet scheme using a starter from fluorescent lamps. If you adapt it to LEDs, then it will look like this.

To apply it, I had to work a little with the groups of LEDs. After checking the connection of the groups, it turned out that they have the anodes of the extreme LEDs connected to each other. And for a circuit with starters, it is necessary that voltage be applied to the anode through a current-limiting resistor. Consequently, it was necessary to break the anode connection and solder the groups of LEDs with cathodes.

A miniature case to accommodate the circuit was not at hand, I had to breed printed circuit board under the dimensions of the case of a Chinese LED garland repaired by one's own hands. The scheme in *.lay format can be downloaded HERE. As you can see, all the details are placed very compactly. During the operation of the LED garland, the resistors heat up, so I had to make about 25-30 holes in the case for ventilation with a drill with a diameter of 1 mm.

A little about the details. Starters from fluorescent lamps can be taken both at 220 volts and at 127. Only the blinking speed of the garland will depend on this. Resistors MLT-2 or five-watt (but better than the latter), with a resistance of 15-20 kOhm. Diodes are designed to pass through themselves the reverse current of the network - 1N4007 or any others that are designed for a current not less than that which flows in the circuit. They can be taken from the diode bridge of the LED garland if they remain intact. ATTENTION! All details are under high voltage, take this into account when assembling and operating the circuit.

That's actually all. As you can see, repairing a New Year's garland with your own hands is not so difficult. A video with an example of how the repaired garland works is posted below.

Pages:

best-chart.ru

How to fix a Chinese garland: diagram :: ashanet.ru

If, on the eve of the New Year, you unexpectedly find out that the old garland that has been decorating the Christmas tree for many years is no longer working, you should not rush to buy a new one, because there is always a chance to repair it yourself. As a rule, such Christmas tree lamps are not such a complicated design.

Therefore, if you carefully check the possible malfunctions, then you don’t have to wonder how to fix the Chinese garland, the circuit of which is not difficult. So, if the contact wires came off in the garland, the light bulb burned out, or the mode switching was disturbed, then you should not throw it away. It is enough to use some effective tips.

The colors in the garland do not burn: what to do?

The most time-consuming breakdown is the one when the change of colors in the Chinese garland is disturbed. The scheme for solving the problem, if it is simple, then restoring the previous state of the device will not be easy. Job disruption color mode indicates that the bulbs in the corresponding section have burned out.

Before proceeding directly to the repair, it is recommended to disassemble the cover of the switch, which acts as a control unit, and check the reliability of the connections, especially the contacts soldered to the board.

Chinese garland repair: scheme

If at first glance there are no signs of a breakdown, then it means that it is safe to say that the light bulb has burned out. Modern Chinese garlands are arranged in such a way that all bulbs of the same color are connected in series. And if one of them burns out, the light on the entire electrical branch will go out. To fix the breakdown, you must use the Chinese LED garland circuit.

First you need to cut the garland into two equal parts and ring both sections. Then similar actions should be performed with the non-working side - cut into two halves and check again. Similar actions are carried out until it is possible to determine which of the bulbs is inoperative. It should be noted that this method is recommended to be used only if the electric Chinese garland, the circuit of which allows you to speed up the process, is not disassembled.

Methods for determining the malfunction

The process of restoring the health of the garland can be accelerated. To do this, you need to take a tester and attach needles to its ends instead of probes. Then, sequentially, with their help, punch through each of the sections of the chain so that the needle passes to the current core. It is necessary to determine where the section resistance differs significantly. In a similar way, you can determine the breakdown and repair it much faster, without making a lot of effort.

As a rule, the old Soviet garlands for the New Year tree are much more convenient in this regard than the Chinese garland. Their schemes are almost similar, but the design is noticeably different. In Soviet light bulbs are screwed into cartridges. Therefore, it is possible to determine which of them is in working condition, without a soldering iron and an ohmmeter, only by elimination. This method is that you should take a working light source and alternately screw it into the cartridges. Another way with the help of a tester is that it is necessary to measure the resistance of each individual lamp until you can find a burnt one.

Before trying to fix the garland, it is recommended to check the integrity of the common wire. For accuracy, you can refer to the scheme of the Chinese garland. On one side of the board, you can see 5 soldered wires, 4 of which are for glowing colors, and one is common. And if the common wire breaks, then it must be soldered.

What to do if the light does not turn on at all?

If, after studying the scheme of the Chinese Christmas tree garland, it was not possible to find the cause of its breakdown, it is recommended to make sure that it is not the LEDs. In this case, check the control unit and power cord. First you need to make sure that the cord is intact, since there is a possibility that it was interrupted, or there was a break in the contact connections at the connection to the microcircuit. Then you need to try to check the reliability of the soldering of the contact connections to the board. Of course, in order not to suffer, you can purchase a new garland, however, if you want to fix the device, then you should act.

So, the control unit can be replaced with a starter from fluorescent lamp at 220 volts. First, it is recommended to check the connection of the LEDs. If the extreme elements of the groups are connected by anodes to each other, then it will be necessary to redo the circuit and connect the LEDs with cathodes. The point is that the voltage to the anode to normalize the operation of the starter must be supplied through a 5-watt resistor, while the resistance is 15-20 kOhm. In addition, additional diodes will need to be included in the circuit, which will pass the reverse current of the network through itself. In this way, the LED Chinese garland is repaired at home.

As you can see, you will have to spend a lot of time and patience to repair the garland. Therefore, if it is not so expensive, it is recommended to simply replace it with a new, better one. It is important to note that if it was the LED that burned out, after which the operation of the entire section was disrupted, then the serviceable element should be soldered, strictly observing the polarity.

Broken light bulbs

If the light bulbs are broken and there is a desire to repair the device, then it is advisable to simply replace the damaged light source. It should be noted that the replacement is carried out only with the power turned off to avoid electric shock. In such situations, you should pay tribute to unbreakable light bulbs, since you do not always have to deal with malfunctions.

So, if it turns out that the garland does not work, then you should try visually and with the help of a tester to determine the problem area and cut it out. After that, the working sections must be connected using special connectors. On this repair can be considered completed.

Finally

As a rule, breaking a garland before the New Year is not always pleasant, but it is quite possible to repair the old one or purchase a new one. It is important to remember that for repairs you need to have special knowledge, for example, work with the board and change light bulbs. Therefore, in order not to lose nerves and time, it is recommended to buy a new New Year's garland.

ashanet.ru

Repair-alteration of the Christmas tree garland | Articles catalog | katastat.ru

Similar Christmas tree garlands are common everywhere. They are pretty cheap and just as unreliable. Next, we will talk about cases when a small control unit burns out with a board shown in the following photos:

The initial circuit for turning on the garland looks something like this:

Diagram of a Chinese Christmas tree garland

I can’t vouch for the accuracy, since neither the conductivity of the transistors, nor whether the transistors checked it.

The transistors in the real circuit are clearly not simple bipolar ones, but this does not matter for further alteration, since the chip (control circuit) usually burns out and all electronics become unrecoverable.

The first switching option involves paralleling all the garlands. And you can do it directly in the block. The four wires coming from the terminals of the transistors are connected to each other and to one of the wires of the power cable of the circuit. The common wire, the fifth one, which is not coming from the transistor, is connected to the second wire of the cable. The control circuit can be disabled by removing the diode and resistor. The final diagram should look like this:

With this inclusion, the bulbs, of course, do not blink and at the same time they heat up quite a lot. Apparently, the original version is designed for a pulsed mode of operation and, if turned on constantly, the garland will quickly fail. To limit the load, it is better to turn them on in a different way:

Scheme of parallel-serial connection of Chinese Christmas tree garlandsThe fifth wire is “common” insulated

In this case, it is better to get rid of the box. The fifth “common” wire is insulated. With this scheme, nothing is already heated, although it does not blink. Light bulbs do not burn as brightly as in previous version, but the garland itself becomes reliable and safe.

To make the bulbs blink in the circuit, you can use a starter from the throttle circuits of fluorescent lamps. Turn it on in series with the entire garland. When using one starter, the garland flashes sharply and irregularly. Therefore, it is better to use two starters included in the break of two wires of the garland, as in the following diagram.

This inclusion of cables makes switching lamps smooth. The colors seem to shimmer, it turns out that the two colors almost do not go out, only the brightness of the glow changes.

You can connect the starter to the wires of the garland without soldering using a single-core wire, for example, a crossover

At the end of the starter terminals, small holes about 3 mm deep are drilled with a 1 mm drill. 3 mm stripped cable cores are inserted into the holes and the aluminum terminals are compressed with force with pliers.

Crimping wires in the aluminum terminals of the starter (can be soldered with a DSP)

A similar connection can also be made by soldering, but for this you will have to use zinc-tin solder (TsOP). You can also use factory connectors from fluorescent lamps, but the dimensions of the switch housing will have to be doubled

The housing for the switch will have to be selected or made new, since two starters will not fit in the old box. In addition, the starter motors noticeably heat up during operation, and this must be taken into account in the manufacture of the housing.

Do not forget that all elements of the circuit, both Chinese and home-made, are under life-threatening voltage when turned on, and work on assembling the circuit must be carried out after disconnecting from the mains.

Articles catalog: KataStat.ru

katastat.ru

We are all familiar with Christmas tree garlands, consisting of multi-colored light bulbs. However, in recent years, products based on led light-emitting diodes have become very popular.

How they are arranged, what connection scheme they have and what to do if the garland stops glowing, we will consider in detail in this article.

What is a Christmas tree garland made of?

What is a garland of LEDs, is it worse or better than usual?

What is a garland of LEDs, is it worse or better than usual?

Outwardly, this is almost the same product as before - wires, light bulbs (LED), control unit.

The most important element is of course the control unit. A small plastic box on which all kinds of backlight operation modes are indicated.

They change with the push of a button. The block itself can be with a fairly well protected level of moisture and dust protection IP44.

What does he have inside? To open it, use the sharp tip of a knife or a thin screwdriver to pry the latches from the bottom and take off the protective cover.

By the way, sometimes it is glued, and not just sitting on snaps.

First of all, inside you will see the wires soldered to the board. A thicker wire is usually a mains wire that supplies 220V.

Soldered on the board:

- controller that creates all the lighting effects

- thyristors, each of them goes to a separate channel of the garland

- resistors

- capacitor

- and diode bridges

The number of board elements depends primarily on the number of light channels of the garland. More expensive models may have a fuse.

The number of board elements depends primarily on the number of light channels of the garland. More expensive models may have a fuse.

Scheme of the LED garland

network AC voltage through resistors and a diode bridge, already in a rectified form and smoothed through a capacitor, is fed to the supply controller.

In this case, this voltage is supplied through the button, which is open in the normal state. When you close it, the controller modes switch.

The controller, in turn, controls the thyristors. Their number depends on the number of backlight channels. And after the thyristors, the output power goes directly to the LEDs in the garland.

The more such exits, the more diverse the color patterns the product can have. If there are only two of them, this means that only two parts (or halves) of the garland will work in various modes- some lights go out, others light up, etc.

In fact, these two lines of diodes will be connected via two channels in series. They will connect with each other end point- the last LED.

If for some reason you are annoyed by the flashing of the garland and you want it to glow evenly with only one color, it is enough on the reverse side of the board to short-circuit the cathode and anode of the thyristor using soldering.

The more expensive garland you have at your disposal, the more outgoing channels and wires will leave the control board.

At the same time, if you follow the tracks of the board, one of the mains voltage leads is always supplied directly to the final LED of the garland, bypassing all the elements of the circuit.

Causes of the malfunction

Situations with malfunctions of the garland are very diverse.

Situations with malfunctions of the garland are very diverse.

At the same time, remember that the most important element - the microcircuit on the board, "burns" very, very rarely.

Approximately 5-10% of all cases.

- Bad contact on the wires

- LED in one of the bulbs

- Capacitor

- resistance

- One of the diodes

- One of the thyristors

- Controller chip

Bad soldering

If your backlight suddenly stops working, first of all, always check the soldering of the supply and outgoing wires. It is possible that the entire contact was held only by hot melt adhesive.

It is worth moving the wiring and contact anyway.

The most common problem with Chinese garlands is the use of very thin wires that simply break off at the solder points on the board.

To prevent this from happening, all contacts after soldering must be filled with a thick layer of hot melt adhesive.

And when stripping such veins, it is advised to use not a knife, but a lighter. Instead of chipping away the insulation with a blade, heat it up a bit and melt it with a lighter fire.

After that, simply remove the outer layer with your nails without damaging the cores themselves.

LED damage

If the wire contacts are in order and you sin on one of the diodes, how can you check its malfunction? And most importantly, how to find it among the whole series of light bulbs?

First of all, unplug the garland from the outlet. Start with the last diode. A power cable comes to it directly from the control unit.

An outgoing conductor is soldered to the same leg. It goes to the next branch of the light channel. You need to test the diode between its two power wires (input-output).

You will need a multimeter and its somewhat modernized probes.

To the tips of the probes of the tester, tightly wrap thin needles with a thread so that their tip protrudes a maximum of 5-8 mm.

From above, wrap everything with a dense layer of electrical tape.

Since the LEDs are soldered, just pulling them out of the light bulb as in ordinary garlands will not work here.

Therefore, you will have to pierce the insulation of the cores to get to the copper cores of the wiring. Switch the multimeter to the diode continuity mode.

And you begin to sequentially pierce the supply wires near each suspicious diode.

If your garland is not 220V, but 12V or 24V, which is connected from such a power supply:

then the working LED from the multimeter battery should light up.

If this is a 220V backlight, then check the readings of the multimeter.

On the working elements, they will be approximately the same, but the faulty one will show a break.

The method is certainly barbaric and damaging the insulation, but it is quite working. True, street garlands after such punctures are better not to be used outdoors.

Chaotic blinking

There is a situation when you turn on the garland and it starts blinking randomly, then brighter, then dimmer. Changes channels by itself.

There is a situation when you turn on the garland and it starts blinking randomly, then brighter, then dimmer. Changes channels by itself.

In general, one gets the impression that this is not some kind of factory effect, but as if the garland "has gone crazy."

The most common problem here is the electrolytic capacitor. It may swell a little, swell, and this will be clearly visible even to the naked eye.

Everything is solved by replacing it. The denomination is indicated on the case, so you can easily purchase and pick up a similar one in radio parts stores.

If you changed the capacitor, but this did not give an effect, where to look next? Most likely one of the resistors burned out (broken). Breakdown visually determine quite problematic. You will need a tester.

You take resistance measurements, having previously recognized its nominal (normal) value by marking. If it doesn't match, change it.

Part of the garland does not shine

When any of the channels on the garland does not work completely, there can be two reasons.

For example, a breakdown on one of the thyristors or diodes responsible for it.

To be sure of this, simply unsolder the wiring of this channel on the board from your place and connect the adjacent channel there, which is obviously working.

And if at the same time another channel also stops working, then the problem is not in the garland itself, but in the components of its board - a thyristor or diode.

Check them with a multimeter, find the right parameters and change them.

The garland shines dimly

There are also not quite obvious accidents, when the LEDs of a separate channel seem to be on, but rather dimly compared to the rest.

What does it mean? The controller circuit is working fine. When the button is pressed, all modes are switched.

The dialing by the tester of the parameters of the diode bridge and resistance also does not reveal problems. In this case, it remains to sin only on the wires. They are already quite frail, and when such a stranded wire is torn, its cross section decreases even more.

As a result, the garland is simply not able to start the LEDs in the nominal brightness mode, since they simply do not have enough voltage. How to find this torn vein in a long garland?

To do this, you will have to walk along the entire line with the handles. Turn on the garland and start moving the wires near each LED until the entire backlight lights up in full force.

According to Murphy's law, this may be the very last segment of the garland, so be patient.

As soon as you find this area, pick up a soldering iron and disassemble the wires on the LED. Clean them with a lighter and re-solder everything.

Then isolate the place of soldering with heat shrink.

New Year holidays come as always unexpectedly and bring with them a lot of pleasant troubles. It's time to think about gifts, especially for children, for adults, set the table, pick up good music and be sure to put up a Christmas tree to dress up so that the guests have fun and feel comfortable. And the first thing to be hung on the Christmas tree is, of course, Christmas tree garlands. All other toys, as a rule, are hung after the garlands. Next, we will talk about the device of a variety of very different New Year's garlands - old and modern.

In ancient times, when there was no electricity, and the New Year was already celebrated, special New Year's candles were lit on the Christmas tree. This decoration was very flammable. But these times have already passed, everyone began to use electric garlands.

These were ordinary small light bulbs from flashlight or from the illumination of the scale in the radio, connected in series. From such light bulbs, garlands were made by enthusiasts mainly with their own hands. They just picked up a soldering iron, who, of course, knew how to use it, took the wire and light bulbs, and after a while the New Year's garland was already hanging on the Christmas tree.

A little later, New Year's garlands began to be produced industrially. Let's go various designs small-sized lamp sockets and colored shades of various shapes. Sometimes the plafonds were made transparent, and the lamps themselves were painted.

Flashers and blinkers

But calmly looking at the luminous New Year's garland is somehow sad, I want the soul to turn around. Apparently, this is facilitated by some flashing of the garland. In general, a flashing garland attracts with its beauty, and even with the expectation of some kind of miracle or surprise. If there are several garlands, then it is possible to get various lighting effects, for example, a running fire, a running shadow, running twos and threes, as well as many other interesting effects.

Once such designs were developed by radio amateurs, these schemes were published in amateur radio magazines, as a rule, in the November issues. But these magazines, under the conditions of socialist mismanagement, arrived almost a month late, so by the New Year it was possible to make only last year's flashing light.

Microcircuits with a low degree of integration, primarily K155 and K561 and their varieties, were used as the element base. As an example, we can cite a diagram from the Radio magazine No. 11, 2002.

The basis of the circuit is a DD2 counter of the K561IE16 type, which controls four LED garlands through the keys on the DD3 chip and transistors VT4 ... VT7. The most interesting thing is that the UMS8-01 musical synthesizer chip is used as a master oscillator. Such microcircuits were once used for voicing children's toys and musical calls: they simply played the melodies recorded in them.

So in this scheme, the output sound signal It is also used to clock the counter. One can only guess how the pictures generated by the LEDs will look against the background of this sound. Naturally, the music also sounds through the speaker.

In the magazine "Radio" No. 11 of 1995, a scheme was published under the name "Automatic device for smooth control of a garland" by A. Chumakov. The circuit provides alternately smooth ignition and extinguishing of the garland at a speed set by the control unit. The device diagram is shown in Figure 1.

Rice. 1. Scheme of automatic garland smooth control

If you look closely, the circuit is a triac power controller, made on a two-base transistor KT117A. Only the charge rate of the capacitor is not changed manually using variable resistor, but by switching individual resistors using a counter - decoder K561IE8. For comparison, Figure 2 shows a diagram of a phase power controller using a two-base transistor KT117.

Rice. 2. Scheme of the phase power regulator

Microcontroller control of the Christmas garland

As designs on microcontrollers appeared in amateur radio creativity, Christmas flashers, or as they are respectfully called “automatic lighting effects”, also began to be developed on microcontrollers. The most exotic design was published in the Radio magazine No. 11, 2012, p. 37 under the title “ Cellular telephone manages a Christmas tree garland”, author A. Pakhomov.

The design was based on a board from a faulty Chinese garland. The author writes that he was attracted by the originality of the output stage, controlled directly from the MK. He recalls those flashers that were built on the K155 series microcircuits, powerful KU202 thyristors (there were simply no others), and in general, a Christmas tree itself could be put on such a flasher.

And here it was enough to change the controller on the faulty board, write a program with lighting effects and supplement it with some kind of control panel. This remote control was an old Siemens C60 phone that was lying around idle. The microcontroller AT89C51 was used as a manager. What came out of this is shown in Figure 3.

Rice. 3. Scheme of microcontroller control of a New Year's garland (click on the picture to enlarge)

Although this controller is now obsolete and discontinued, it is one of the the best developments by Intel, hereinafter manufactured by Atmel. The constructs on this MK never freeze, they do not require a watchdog timer. The command system is so good that it still remains unchanged, despite the appearance of new models of the MSC-51 family.

Simple LED flasher

A little higher than the article by A. Pakhomov in the same magazine “Radio” No. 11, 2012, an article by I. Nechaev “From the details of CFL. LED flasher for a New Year's toy. The circuit is made on a three-color LED and three DB-3 symmetrical dinistors "mined" from boards from faulty energy-saving lamps.

Rice. 4. Scheme of a simple LED Christmas garland

Each channel of the three-color LED is controlled from its own relaxation generator assembled on DB-3. Consider the operation of the circuit using the example of one channel, for example red.

The capacitor C1 through the resistor R3 is charged from the rectifier R1, VD1 to the breakdown voltage of the dinistor VS1 (32V). As soon as the dinistor opens, the capacitor C1 is discharged through the red element of the three-color LED, the resistor R4, and the dinistor VS1. Then the cycle repeats.

The red, green and blue elements of a three-color LED have their own generators and work independently of each other. At the same time, the frequency of each generator is different from the other, so flashes occur with a different period. The design is placed in a transparent case and can be used, for example, as a Christmas tree top. If you add a white LED HL2 to the circuit, then colored flashes will occur on a white background.

Many more descriptions of the designs of domestic radio amateurs, old or new, good or bad, could be given, but all of them were made almost in single copies. Modern stores are completely littered with electronics made in China. Even New Year's garlands and those Chinese ones, besides, they are now worth nothing.

Literally a year or two ago, such New Year's garlands were sold at a price of 100 ... 200 rubles, and on the eve of the current 2014 New Year, they are sold in stores with the name "All for thirty-eight." The real price is somewhere in the "Mega" one and a half - two rubles. Let's see what's hidden inside.

Chinese New Year Garland Controller

Outwardly, everything looks very simple. A small plastic box with one button, which includes a power cord with a plug, and four garlands come out. When plugged into the socket, the garlands immediately begin to alternately show all the lighting effects. There are 8 of these effects in total, as indicated by the inscriptions under the button. By pressing a button, you can simply immediately switch to the desired light pattern.

If you open the box, then everything inside is also quite simple, as shown in Figure 5.

Rice. 5. Chinese LED string control board

Here you can see all the details. The microcontroller, as always, is made in the form of a drop of black compound, next to it is a control button, an electrolytic capacitor, a single diode and three output thyristors.

There is a place on the board for the fourth thyristor, and if you solder it, you get one more additional channel. In the controller, this channel, as a rule, is also flashed. It's just that our Chinese friends saved on one thyristor. Those who have ever opened such control units assure that in some boxes only two thyristors are soldered. The economy must be economical! Our, still Soviet slogan.

Despite such a small size, PCR406 thyristors have a reverse voltage of 400V, and a forward current of 0.8A. If we assume that the load consumes only 25% of the maximum current, then at a voltage of 220V it is possible to switch the power 220 * 0.2 = 44 (W).

Figure 6 shows a printed wiring, according to which you can draw a circuit diagram, which has been done repeatedly. Here you can see the holes for the fourth thyristor, just the one that was saved.

Fig.6. Saving details on the example of a Chinese garland

The savings also affected the diode bridge: instead of four diodes, only one is used on this board. And everything else corresponds to the scheme shown in Figure 7.

Rice. 7

The mains voltage is rectified by the diode bridge VD1 ... VD4 and is fed through the quenching resistor R1 to the 10th output of the microcontroller. To smooth out the ripple of the rectified voltage, an electrolytic capacitor C1 is also connected here. The current consumption of the microcontroller is quite insignificant, so in the future, instead of a bridge of four diodes, the Chinese decided to get by with one.

A small note about increasing the reliability of the entire circuit as a whole. If you solder a zener diode with a stabilization voltage of 9 ... 12V in parallel with capacitor C1, then the probability of failure of the MK or simply explosions of thyristors will decrease much.

Deserves special attention resistor R7 connected to pin 1 of the microcontroller directly from the mains wire. This is done to synchronize with the network in order to carry out phase power control. This is exactly what works at the time when the garland lamps smoothly light up or go out.

On the right side of the microcontroller there are thyristor control outputs and a control button, which was described above. Thyristors turn on at the moment when the corresponding output of the MK appears high level, then the corresponding garland is lit.

Sometimes New Year's Eve garlands of high power are required, from several hundred watts and above. In this case, the considered circuit can be used as "brains", it is enough just to supplement it with powerful triac switches. How to do this is shown in Figure 8.

Rice. 8. The scheme of the New Year's garland of high power

Here you should pay attention to the fact that the MK is powered from a separate source galvanically isolated from the network.

LED garlands

They use the same controller with one button, the same thyristors, but instead of bulbs, garlands are made up of LEDs of three or four colors. Each garland contains at least 20 LEDs with current limiting resistors.

Moreover, the design of such a garland is just a Chinese riddle: in the first half of the garland, a resistor is soldered to each LED, and the remaining ten pieces are simply connected in series. Again, saving ten resistors at once.

Such a design can, apparently, be explained by production technology. For example, the first half is assembled on one line, which is with resistors, and on the other line without resistors. Then it remains only to connect the two halves into one whole. But this is just a guess.

Hello friends! Fairy times are coming: children and adults have holidays, a Christmas tree on the balcony, vodka and sausage in the refrigerator.

And, the tree has already been brought in? Are you dressing up? It's clear. And they probably saved on garlands, Schaub was enough for sausage.

Then take your time. Conduct an audit of the products of the Chinese brothers before winding them on a festive tree.

Chinese garlands are good at a low price. This is where the charms end, and the troubles begin: from fading in the midst of fun to electric fireworks with a fire.

Option one, classic

Photos of my countryman Pavel Shepelev.

A garland of colored incandescent bulbs, a control unit in a green box.

Scenario: we turn it on for verification, we get “BDYSCHSHCH!” with fire and stench, as much plastic flowed. The control unit burned out completely, the reasons are not guessed.

Treatment: nafig green box, garlands in parallel. The garlands shine, though they do not blink.

Option two, fashionable

Multi-channel multi-mode garland on LEDs (light-emitting diode). Good for everyone: bright and colorful and not afraid of concussions, BUT! The Chinese again even wised up for economic reasons. In series with each branch of lights there is a 3 kOhm resistor and some kind of inhumanly low power, I believe - less than 0.125W!

There are 10 such resistors in total. and they all heat up fiercely. And the meanness is that it is not noticeable. You won’t even guess about the existence of these resistors until they start to burn - they are so cunningly mounted.

This garland worked 1 NG. Here's what I found on inspection today.

Low-power resistors overheated, burned, even soldered from LEDs and wires. Only the outer plastic clip kept them in place. When disconnected, the solder cooled down and everything could be started from the beginning.

The error did not appear!

The standard resistor is next to the 0.25W resistor.

I decided to put more powerful resistors and observe. The plastic clip was cut with a clerical knife, the resistor was replaced. The procedure is done for all detected resistors.